Jul 05, 2024

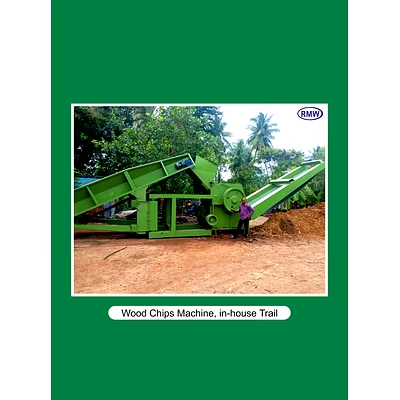

Wood Chips Machine (Rag chopper ) – 24” x 27 ½”2

Size 24”X27 ½”Dia head size, running blade 6 no,

bed blade 3no

Main soft 5 ½” Dia, Bearing size 5”dia

It suitable heavy fly wheel 2 Nos

Machine body 1”with plate fabricating

Discharge conveyor type with 1HP 1500 RPM motor

Feeding conveyor movable type with 2HP motorized

gearbox type

Gear box equipment’s

The machine run by 50 HP 1500 RPM motor (50 Hp

motor not in our scope)

Spare Blades – 1 Sets(9 No’s)

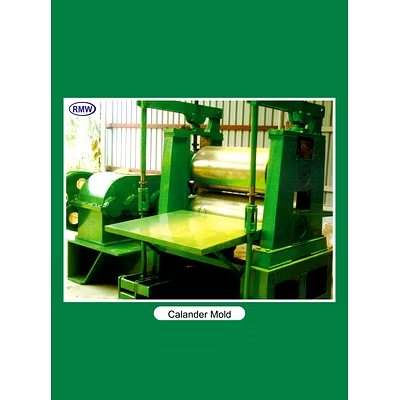

Calendaring Machine

CYLINDER MOULD

• Main mould (40’’OD X 48’’Breadth) drum.

• It’s suitable 6 no’s arrow wheels and 2 no’ side wheel. Centre fixing with 3’’ main shaft.7 ft length with suitable stand bearing blocks and sleeves. Rubber roll 10’’ dia 48’’ Length 2½’’ bearing size 66’’ length.

Tension roll

• 8 no’s

• Cutting drum-20’’ dia *48’’ length

Others

• Belt adjustment screw rod set-4 Sets

• Rollers are mounting with frame

• Frame fabricated by-6’’ * 3’’ channel.(58’’ breadth *68’’ Height) 120’’length.

Knife Grinder

Specification:

Including 2 HP motor (3000 rpm) with Trolley Bed, Bed size 3Feet/21”

The frame is made by 2”x2.5” Square Pipe

Knife holder Adjustment type front and back

Motor bed up and down Moving by screw type

Cylinder Mold

Paper Moulde and Board Moulde Machine Approximate 77 ½” Height X 52 ½” Breath X 84” Length.

Cutting Drum Size - 20” Dia X 44” Length, Bearing Size 2 ½” -2 set, Total Length 60” – 1 No (Double slotted).

Baby Rolls- 3” Dia X 44” Length, Bearing Size 1 ½” (1 ½” X 3” X 44”) Total Length 60”-6 No’s + 1 No’s Spare.

3.54 Gear Box (election)-1 No, it suitable motor and gearbox bed.

Rubber Roll (Press Roll) -45-50hrc 10” Dia X 44” Length Bearing Size.

2 ½” (2 ½” X 9 ½” X 44”) Total Length 60”-1 No.

Conveyor Belt Adjustment And Tightening Setup By Screw Rod System

The cutting drum is made up of MS.

The Frames are Made Of 6” X 3” Channel.

Running Mesh + Spare Mesh 1No’s.

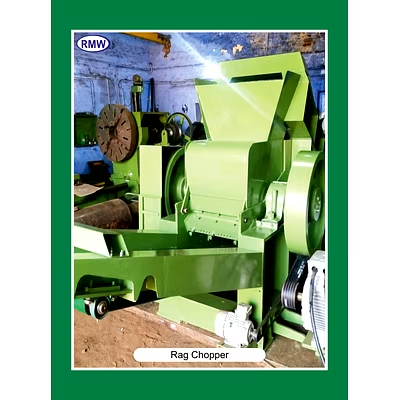

RAG CHOPPER - CLOTH CUTTING

Machine Body Fabricate by 1” MS Plate.

Capacity 1000 kg per hour.

Size 24” X 27 ½” dia head size, Suitable heavy play wheel - 2 Nos.

Running blade - 6 Nos and Bed blade – 3 Nos.

Main soft 5½” dia, bearing size 5” dia.

Machine body 1” plate fabrication, Feeding Tray type, Output Delivery Conveyor Type

Wood Chipper Machine 42"x44"

RAG CHOPPER - 42” x 48” Crunch Machine :

• 1 MACHINE Capacity 4000-5000 kg per hour

• Size 42” 48” Dia head size running blade 12 No’s, bed blade 3No’s

• Main soft 6 1⁄2” Dia 1 NO’S, Bearing size 6”dia 1 NO’S

• It is suitable for heavy flywheel 2No’s

• Machine body 1 1/4”with plate fabricating

• Discharge conveyor type

• Feeding conveyor movable type with motorized gearbox type

• A 100 HP 1500 RPM motor runs the machine's Main HEAD.

• Spare Blades 1 MACHINES – Sets(15 No’s)

• 25mm Dia Hole Mesh-1 set

• Main Shaft With EN8 GRADE (UV Test report)

• Fly Wheels, Pulleys or Cast Iron (30 Grade)

• Steel Bearing Block(6”)

• Machine Body MS Plate(UV Tested)

• Delivery conveyor approximate height 15 feet

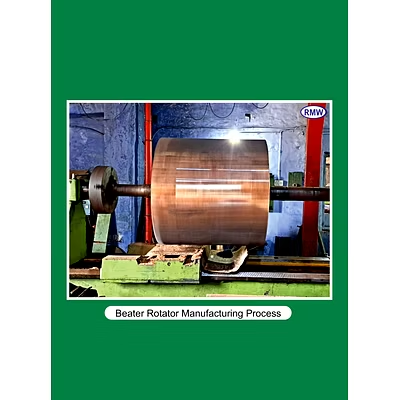

Single Head Beater 30"X36" - 100 kg

MODEL: Single Head Beater 36’’X30’’ Machine – 100 Kg

Specification:

Beater head size 36” dia X 30” breadth head size Main shaft 5.5” dia

10ft Length shaft metal EN8 Grade.

Bearing and pully size 4”

Blade size 8mm thick x 5 ½” breadth x 29 ½” mm length – 72 Nos.

Roater 3 CI castiron flanges with slotted, locking blade and locking

Wood, face and outer dia machining head -1No.

V pully 36” X 4” SPC sec -1 No. 6”x4 SPC

Suitable bearing and block sleeves and accessories

Base bed Box -1 no, Knife bed Box -1 no, Safety cover -1 no.

Discharge mouth -1 set, Lift Hook -1 no.

Lifting system (Screw Rod) worm and worm wheel System Type -1 Set

The flanges are Cast Iron, the Main Shaft EN8, and the Blades are mild Steel.

Beater Legs, Bearing Bar, and Base frame are mild steel

SS Beater

Model: 21” X24” SS Beater Machine (1 Complete Machine)

• Beater Roater 21”Bx24” Dia,

• Main shaft 3” Dia 90”x60”

• No of Blades 48.

• Roater up and down Auto Feeding Motorized Gear Box type.

• The machine is suitable for all equipment

• Roater Tank 5mm SS304 Grade Sheet.

• Roater with 8mm Plate and Suitable (80 mm) Main Shaft, 3” Dia Bearing and Pulley Size.

• Base Bed Knife Box – 1no Including

Note:

• Bearing Bar and Long Leg, Short Leg Base Frame are in MS.

• Roater and Roater Main Shaft, Blades, and flanges are in SS304 Grade.

• Complete 1 Full set of machines. (Excluding Of Erection and Electrical Work)

Double Head Beater 44’’X42’’ Machine -400 Kg

Specification:

• 400Kg Per Batch (Each Batch=3hrs) Per Day=8 Batch, [8x400kg=3200Kg Per day].

• Beater head size 44”dia X 42” breadth 44*42.

• Main shaft (1) 6” bearing size 5” shaft length 12.6” – 1 No.

• Main shaft (2) 6” bearing size 5” shaft length 12.3” – 1 No.

• Suitable countershaft and motor bed assembly -1 No.

• 40” X 07” SPC, 9”x7” SPC. - 60” play wheel -1 No.

• 20” X 10” SPC - pully wheel 60”x5” -2 no.

• 44” X 42” Beater head – 2 Nos, Safety cover– 2 Nos.

• Suitable bearing and block sleeves and accessories.

• Base bed box – 2 Nos, Knife bed box - 2 Nos.

• Discharge Mouth -2No with Lifting Rod

• Flanges are Cast Iron, Main Shaft EN8, Blades are in mild Steel.

• Beater Legs and Bearing Box, Base frame are mild steels

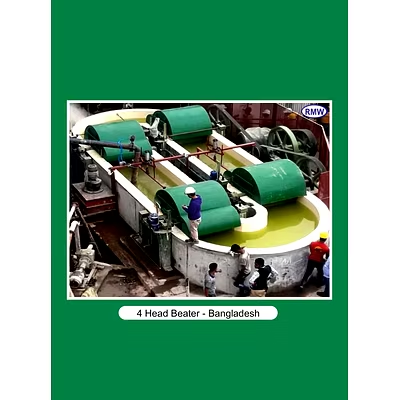

Four Head Beater

44 “Dia x 42” Length

Capacity 4Ton per day

One Batch 800 kg 3½ hrs approximately 6 batches per day

Blade Size 5/16”x6”x42” 96 No.

Main Shaft 6½“Dia, 12 Feet Length (EN8), 5” Bearing and 4½” Pulley Size

Blanches are Cast iron

Suitable Stand with M.S. Fabrication

Lifting Worm & Worm Wheel System, Base Frame,

Safety Wooden Cover, Beater Bed Box with Knife Box

‘V’ Pulley size 5c sec/60”dia or Flats Pulley

Reduction ‘V’ Pulley Size 12”x 40” 8 ‘C’ Section -2 set

30” X10" C section- 2 set

Counter Shaft set and 4” Dia Bearing Black 2 Set

One motor run by two Rotor

Machine run by 100 HP 960 RPM Motor - 2no

One complete machine value without motor (USD 12,750)

Two complete machine values without motor 12,750 x 2 No = 25,500

NOTE: Feeding and lifting automatic motorized method

4 Bed knife box including